Bangladesh has set an export target of USD 50 billion by 2021 for the readymade garment (RMG) sector. The target appears slightly ambitious and sceptical about its attainability after the Holy Artisan Bakery incident in 2016, following which many buyers and foreign nationals became worried about their security. To achieve a target of this magnitude in only five years' time, it will require a steady growth of around 14 per cent in export income per year which appears difficult now with a number of challenges arising - especially security issues and image crisis. Bangladesh's RMG industry is still reeling from the Rana Plaza disaster, Tazreen Fashions fire incident and Holy Artisan attack in recent years.

Physical security practitioners must improve their methods to meet future threats with proactive measures against any threat to garments and textile industry in Bangladesh by an Integrated Security System - which includes intelligence mechanism with technology and physical security - becoming more dynamic than they are today.

Definition of physical security: Physical security is a combination of physical and procedural measures designed to prevent or mitigate threats or attacks against people, information and assets. A physical security programme has the aims to detect, deter, delay, respond and recover.

Physical security practice in industry: Physical security has three important components: access control, surveillance and testing. Such hardening measures include fencing, locks, access control cards, biometric access control systems and fire suppression systems. Physical locations should be monitored using CCTV-like surveillance cameras and notification systems, such as intrusion detection sensors, heat sensors and smoke detectors.

External & internal factor threatening RMG industry's physical security: Physical security controls include preventing unauthorised physical access to secure areas as well as preventing outright physical theft. Insider threats to physical security of a factory can come from current or former employees, contractors, labourers and trusted business partners, including security guards and outsiders like NGOs and paid workers' association.

Several incidents of unrest took place following rumour that a worker had been killed by "ghost" in garment factory as his/her whereabouts could not be known. Outsiders or vested group with the help of insiders carried out acts of sabotage and created unrest in many factories by spreading these sorts of rumour on many a time.

Many RMG industries in Bangladesh were subjected to a sort of uprising by unruly workers on many occasions which posed serious threat to Bangladesh's garment and textile sector. After analysing every incident it was found with tangible evidence that garment workers agitated during the incidents, but it was the outsiders who mainly got involved in smashing, looting, rioting and damaging factory machines and assets.

In many factories, there is no mechanism to get early warning that can indicate any such incident may take place inside the factory. So, it is high time for each factory to have own mechanism to get early information and take precautionary measures beforehand. Although industrial police, Special Branch and National Security Intelligence work on this, it does not help very effectively at the factory level.

Different views like conspiracy and need of integrated security system: There is another side of the coin regarding any incident of unrest. Whenever garment workers take to the street to press home their demands, businessmen come up with a common statement outlining foreign involvement or outsiders' role behind the disorder. A variety of speculations generally spread and creates confusion regarding unrest and causes of any incident related to garment factories.

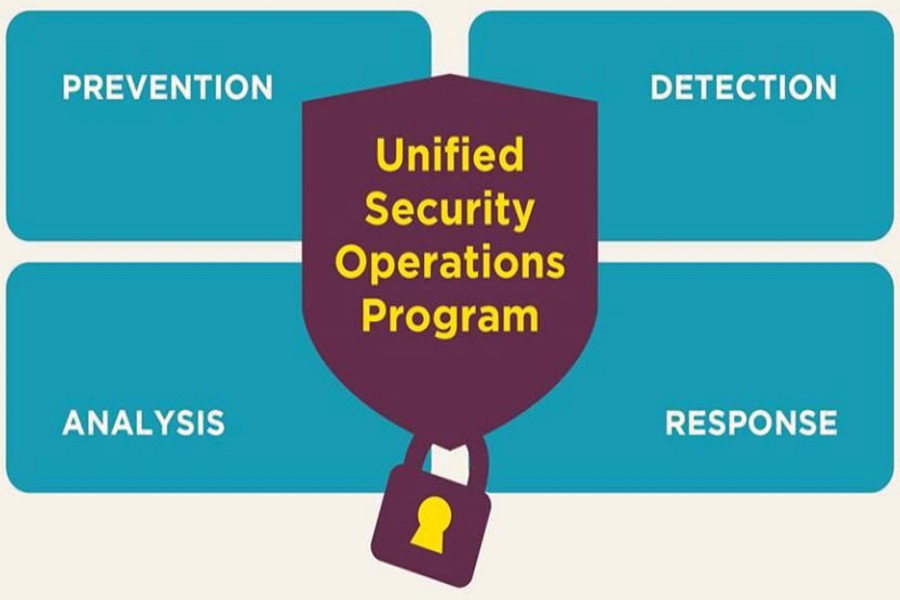

So, there is no authentic mechanism to get a correct picture of unrest, reason behind it and whom to be trusted for solving the crisis. This is where intelligence mechanism along with physical security may help get clear versions in case any incident takes place at garments factories. This will also give a clear picture as to how unrest and crisis can be solved. Under this situation, total physical security system for garment and textile industry needs reorganising and integrated security approach to tackle complex situation is the requirement to meet. Sabotage and attacks cannot be ruled out against RMG industry. Internal intelligence mechanism combined with physical security in garment industry to ensure proper physical security may be termed "intelligence-led security".

Understanding importance of security by garment factory decision makers: One dangerous perception common in many companies is that workplace violence is the problem of the garment company's security department. Security departments in most of the companies represent bare-bones operations and they are quite often among the first departments to be downsized and trim manpower when companies face reduction in order from buyers. Security departments in most of the companies focus on physical security, loss prevention and theft of company property. With their limited staff and large responsibilities in wide area, they have very little scope to learn about what is going on with the angry guy sitting inside that middle cubicle or in front of any machine on any floor. The security department has no mechanism to focus on external affairs and threat that may arise to affect the factory. Statistics show that current employees account for 43 per cent of workplace violence involving the co-workers.

Following any major setback, long discussions take place for a few days and importance is given to security issue. But in reality many top management people do not realise the fact that physical security is an integrated element of production.

Since the company security departments are not omnipresent, they require other people to act as informer and part of intelligence section within the company/factory to be their eyes and ears and alert them of any possible workplace violence.

A proactive stance: Protective intelligence and surveillance detection teams, which are proactive by their very nature, inside the security department of a factory can help by noticing abnormal incidents from within and behavioural aberration taking place inside and outside the factory. Uniformed guards sitting inside the factory entrance and important places have very limited scope to monitor and envisage any threat/risk. Proactive measures by intelligence team of a garment factory can help provide protection and proactive stance side by side the physical security and technological system before any incident takes place.

Proactive intelligence actions for physical security in garment and textile industry includes: (1) Assessing the unusual situation covertly and overtly. (2) Monitoring human activity on important production floor(s) and thereby tracking suspicious or abnormal activity & movement. (3) Keeping rumour under control before it makes a hue and cry. (4) Identifying the troublemaker(s) and make them aware about any grouping. (5) Keeping eyes open for community watching outside the factory premises where factory personnel do reside. (6) Cross-checking of factory personnel's background.

Bangladesh Export Processing Zones Authority (BEPZA) and Industrial Police are having a skeleton intelligence section to monitor the RMG and industry situation and it actually does not exert any direct impact on the factories. Being the country's apex trade body representing the garment sector, BGMEA is having social sector development to monitor situation in the RMG industry.

In Bangladesh, our security element for any industry must be trained on intelligence training and implement an effective intelligence collecting mechanism side by side the physical security arrangement.

Major (retd) Sha Jalal Haider is an Admin and Security professional working in the garment industry. [email protected]

- Saturday, 23 November 2024 |

- Today's FE |

- e-Paper |

- Beta Website