Industrialistion is the process of structural transformation through which resources (especially labour) move from agriculture to industry and more specifically to manufacturing. Industrialisation has several benefits, especially in the long run, such as diversification of the economy, employment generation, technology transfer and welfare improvement of the people. As a result of industrialisation, an economy experiences an increase in the share of manufacturing in Gross Domestic Product (GDP) as the production of manufactured goods increases. Simultaneously an economy also experiences a rise in manufacturing share in employment. It plays a vital role in accelerating the process of economic development of the developing countries. Industrialisation leads to an increase in national income by ensuring the maximum use of scarce resources, and raises the export of manufactured goods. Moreover, industrialisation opens up employment opportunities and thus helps in poverty reduction. It also allows the government to make long-term investments in infrastructure, skills formation and institutional building, which contributes to development of the economy. The manufacturing sector possesses some characteristics which can establish the necessary linkages for sustaining a virtuous circle of growth and structural transformation.

Table 1 shows the top ten and bottom ten countries in terms of average share of manufacturing in GDP out of the 91 developing countries for the period 2012-2016. During this period, China and South Korea were the top two countries in terms of manufacturing value added in GDP of over 30 per cent. In contrast, Hong Kong and Sierra Leone had the lowest contribution of manufacturing to GDP of less than 2.0 per cent. Over the past four decades the East and Southeast Asian economies topped the list in terms of high manufacturing share in GDP. In case of South Asia, only Sri Lanka was able to make it to the top 10 in 2010.

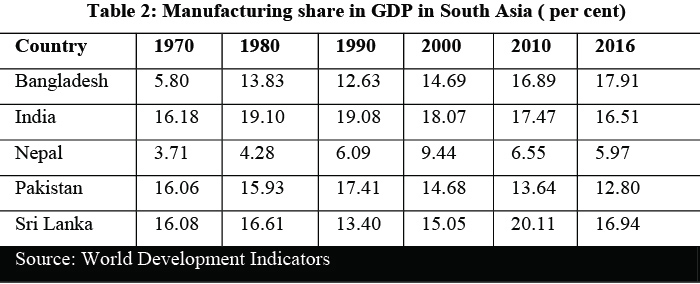

An analysis of the data of the share of manufacturing value-added in GDP for five South Asian countries (Bangladesh, India, Nepal, Pakistan and Sri Lanka) for 1970-2016 (Table 2) suggests that India increased its share of manufacturing value-added in GDP from 16.18 per cent in 1970 to 19.10 per cent in 1980. However, since 1980 India had been experiencing declining share of manufacturing value-added in GDP and the share fell to 16.51 per cent in 2016 which depicts some signs of premature deindustrialisation. The trend in share of manufacturing value-added in GDP for Pakistan declined from 16.06 per cent in 1970 to 12.80 cent in 2016 and for Nepal increased from 3.71 per cent in 1970 to 9.44 per cent in 2000 but declined to 5.97 per cent in 2016. Recently Sri Lanka also showed signs of premature deindustrialisation. Contrary to all other South Asian countries, Bangladesh has been experiencing an increasing share of manufacturing value-added in GDP. In 2016, Bangladesh had the largest share of manufacturing value-added in GDP (17.91 per cent) among the South Asian countries.

CROSS-COUNTRY PANEL ECONOMETRIC ANALYSIS: In order to explore factors that affect manufacturing share of GDP, a cross-country panel econometric analysis has been conducted using a panel data of 107 developing countries for the years 1970-2016. The UN classification for developing countries has been used. In case of developed economies, over the years the contribution of manufacturing value-added to GDP tends to decline. Therefore, we have considered only developing countries in our analysis. All data have been obtained from World Bank's World Development indicators. The fixed effect panel regression results suggest that the size of the population, share of households with access to electricity, lower rate of applied tariff rate, domestic private sector credit as share in GDP, investment as share in GDP, labour force participation rate of younger people (age 15-24), and share of public expenditure on education in GDP have positive and statistically significant association with higher manufacturing share in GDP.

The size of the population can be used as a proxy for the size of the internal demand. There is a significant positive relationship between manufacturing expansion and internal demand so that, other things being equal, countries with larger internal demand tend to have a higher manufacturing share. The access to electricity variable can be considered as a proxy of infrastructure, especially electricity infrastructure, of a country. Electrification is an important factor for industrialisation. Furthermore, an outward-looking industrial strategy allows access to large markets and a growing demand which encourages large-scale industrialisation programmes. Moreover, trade liberalisation helps boost the industrialisation process by ensuring supply of imported inputs at free fair trade prices, providing access to technology and capital and by helping to establish a more competitive exchange rate. The strategies followed by economies which were successful in industrialisation include the adoption of trade liberalisation in conjunction with setting up of special economic zones, export processing zones, and industrial bonded zones as strategies for promoting Foreign Direct Investment (FDI) and supply export-oriented firms with duty-free, tax-free imported inputs. Trade played a crucial role in expediting structural change and industrial development in these nations. The existence of better financial institutions helped influence the industrialisation process by facilitating efficient allocation of resources and ensuring larger private sector credit in proportion to GDP. The presence of an efficient banking system ensured the availability of finance to firms, especially small and medium sized firms and reinforced domestic entrepreneurship helped speed up the pace of industrialisation. The countries with higher levels of private investments, backed by high levels of domestic savings and FDI, were also successful in the industrialisation process. The increased participation of youth in the labour market helps reap the benefits of demographic dividend. Human capital development in the form of sufficient technically and scientifically qualified personnel can help meet the increase of demands and contribute to industrial development. The foundation of a competitive industrial sector can be developed and the appeal of investments can be raised by generating immobile national assets, through education spending in particular. Therefore, any form of industrialisation demands an increase in government spending on education.

Finally, experiences of successful countries suggest that better functioning institutions, capable of guaranteeing better rule enforcement, transparency, management of corruption, and government stability could improve doing business climate and stimulate entrepreneurial spirit. On the contrary, the existence of significant governance deficiencies could render difficult the building up of a solid industrial sector and complicate the leading of a dynamic industrial policy. Therefore, reforms for improved administrative procedures and reduction of regulatory delays are critically important.

It can be summed up that in order to initiate a sustained process of strong industrialisation a boost in investments and an improvement in education are crucial; the management of trade and capital openness are also vital factors; financial sector development and the promotion of both macroeconomic stabilities in the form of lower levels of debt and high levels of political and social stability and institutional stability is essential for achieving sustained industrialisation. In addition, infrastructure development, uninterrupted access to energy and innovation can act as catalysers in the process of nurturing industrialisation.

However, a one-size-fits-all solution does not exist and developing economies have to customise their industrialisation policies with respect to size, economic specialisation, levels of development and institutions.

Dr. Selim Raihan, Professor, Department of Economics, Dhaka University & Executive Director, SANEM.

Sunera Saba Khan, Senior Research Associate, SANEM.