Universal Robots, the leading manufacturers of advanced, light weight robotic arms, has launched in Bangladesh with a vision to expand operations across the country.

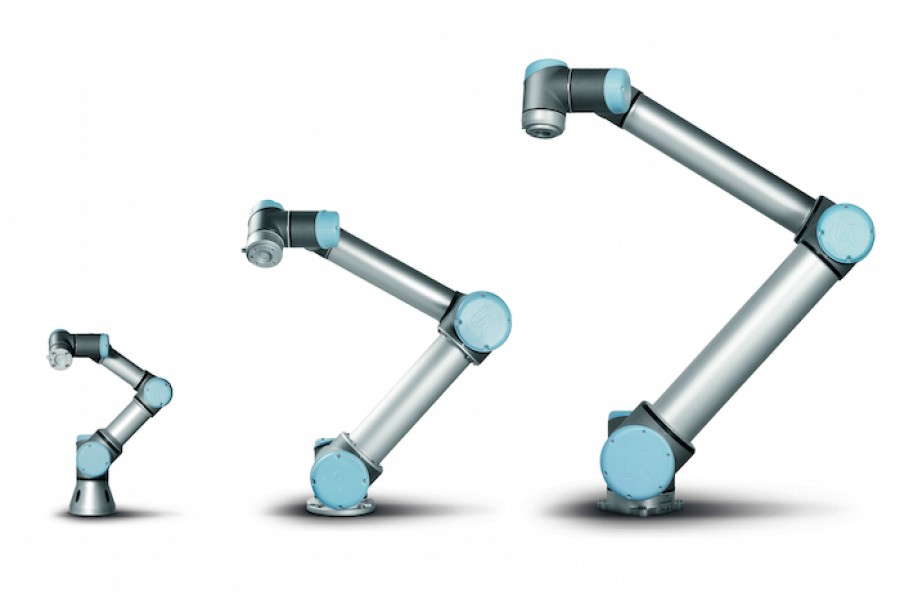

A Universal Robots-manufactured robotic arm is known as UR robot.

The Universal Robots General Manager for South Asia Pradeep David expressed the company's interest in Bangladesh market at a launching programme of Universal Robots in Dhaka on Tuesday, reports UNB.

Danish company Universal Robots first developed in 2008 collaborative robots or co-robots, now dubbed as cobots, which are light-weight, easy to use robotic arms. Cobots are easy to programme, install and their collaborative nature allows them to work side-by-side with the workforce for high-quality output and handling them requires no special training.

They work as a 'helping hand' that helps the human workforce in carrying out monotonous tasks, increases productivity and efficiency.

Pradeep David said, "The collaborative robot is a powerful innovation in the industrial manufacturing sector, enabling automated production with unprecedented flexibility. Our collaborative robot arms automate and streamline repetitive industrial processes. This approach will enable production departments to assign their staff members more creative jobs that provide them with new challenges that add value to the company and at the same time will increase the efficiency and productivity."

He added "Our latest collaboration in India was with an SME in January 2017 which has seen a 300 per cent boost in production, over a brief period of eight months. After successfully venturing into the Indian and Sri Lankan markets, we are looking forward to setting up and growing in Bangladesh as the country can provide us with enormous opportunities to develop."

He also added that "Bangladesh, as a labour - intensive market, employs over three million people in the manufacturing industry. With the advent of modern technologies, the manufacturers are worried that automation will lead to increased unemployment. Bangladesh's industry, mainly garment manufacturing, employs unskilled labour; therefore, falling short in the run to competing in the global markets in terms of output, productivity and efficiency. Introduction of collaborative robots will help boost productivity of the Bangladesh industry by ensuring minimisation of downtime and upskilling of labour."

Collaborative robots or Co-robots or Cobots are light-weight, easy to use robotic arms that were first developed by Universal Robots in 2008. Their latest technological advancement is in sync with Industry 4.0 - automated revolution in manufacturing industry. The idea was for humans and robots to be inter-dependent and achieve what each of them does best. There are a few things that must be done manually, whereas the accuracy, precision and mass production at higher efficiency will be taken care of by the robots.

Universal Robots was co-founded in 2005 by the company's CTO, Esben Østergaard, who wanted to make robot technology accessible to all by developing small, user-friendly, reasonably priced, flexible industrial robots that are safe to work with. Since the first robot was launched in 2008, the company has experienced considerable growth with the user-friendly robots now sold in more than 50 countries worldwide.