A rural youth lacking higher education and enduring various odds has embarked on a successful mission of innovating an environment-friendly technology of generating fuel from plastic wastes such as polythene and plastic bags.

HM Tawhid, a 25-year youth, has only completed his higher secondary school from Govt. Ashek Mahmud College in Jamalpur. He did not get necessary support or guidance from any teacher or scientist. He has been using his utter intellect in innovating the technology to produce fuel from plastic wastes.

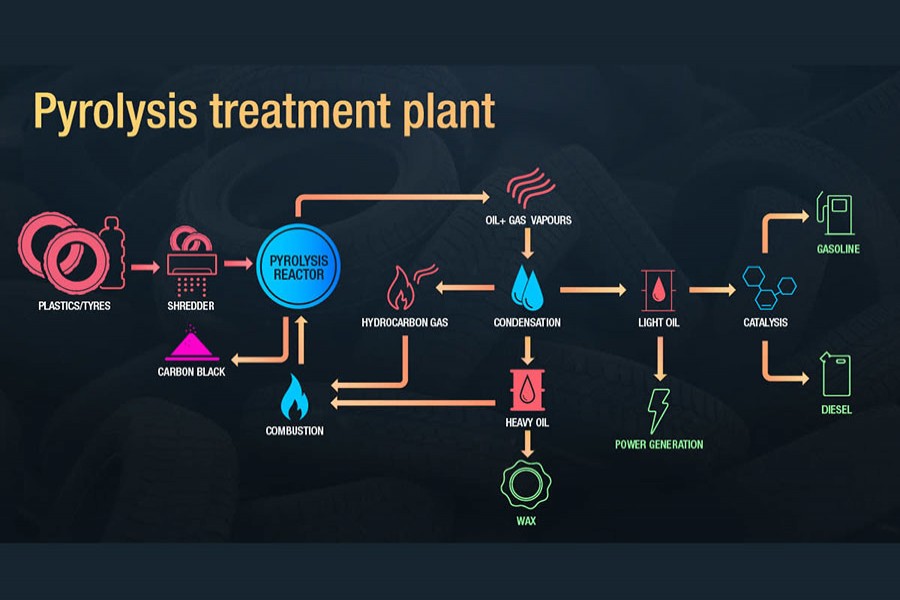

Setting up a plant in Jamalpur municipality with support from Access to Information (a2i) project of the Prime Minister’s Office and UNDP Bangladesh, Tawhid breaks the molecular bond of polythene and plastic and transform it into another form of carbon in which raw fuel (Diesel/Petrol and Kerosene) is found, in addition, the method also produces by-products like coal and gas.

Tawhid uses heat in a high pressure to change the carbon form and convert poly to fuel in 2:1 ratio. If 100kg of poly/plastic is burnt, about 50 litres of fuel will be produced.

The process mainly requires a chamber where polythene/plastic is burnt in high pressure and then those are sent in gas form into three different pipes that is through condenser. In condenser, heat and pressure transmission are given.

After first burn, crude oil, heating in the temperature between 120 and 150 degree, petrol is produced. After burning petrol from 150 to 200 degree temperature, diesel is generated and Kerosene is produced in the temperature above 200 degree.

Taufiqur Rahman, a mentor of a2i’s Fuel from Poly/Plastic Project, said this invention is not only a mere discovery rather it has commercial viability as only raw material of Tk 24 can produce petrol costing Tk 87.

“Under a keen supervision of Access to Information (a2i), we’ve taken an initiative to scale up the project up to 200 kg raw material process plant in a day, and commercially it will be profitable venture after generating 5/7 employments, including the innovator as an entrepreneur,” he said.

Environmental researchers estimate that 9 million plastic items are being dumped daily across the country with only about 10 per cent being dumped into rubbish bins. Over time, the castaway plastic items end in clogging up drains and sewers and pollute rivers and soil, reports BSS.

Taufiqur said the innovation of the young scientist is environmentally sound and it does not create pollution and that is why it is time to know whether the innovation is financially viable on a large scale.

To know that, he said, a new pilot project was launched in Jamalpur municipality area on December 1, 2018. “Once we find the pilot project is commercially feasible, we will launch such project in waste dumping stations of 64 municipalities in 64 districts.”

Then local entrepreneurs will be involved in the projects while a2i project and UNDP will provide technical assistance to run the innovation plants, Taufiqur said, adding that the local entrepreneurs will come forward to invest in the projects when those will be commercially feasible.